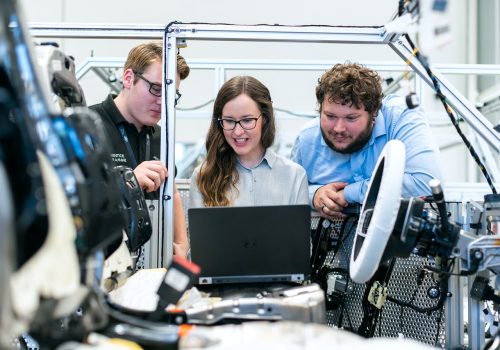

People Power in an Automated World

Automation is reshaping the industrial landscape but behind every smart system is a team of skilled people. As factories grow more complex and technologies evolve rapidly, technical training is no longer optional. It’s a strategic investment. Training equips operators, technicians, engineers, and managers with the knowledge and confidence to run, maintain, and improve automation systems. Without it, even the best-designed infrastructure is vulnerable to misuse, downtime, and inefficiency.

What Is Technical Training in Industry?

Technical training in an industrial setting refers to structured education programs that build practical skills and theoretical understanding of systems such as PLCs, HMIs, robotics, electrical safety, instrumentation, and data networks.

Training can take many forms:

- Hands-on sessions with live equipment

- Simulation-based learning using virtual systems

- Classroom theory on control logic, regulations, and system design

- Remote courses or digital modules for self-paced learning

These programs may be developed in-house, offered by equipment vendors, or delivered by specialized training providers.

The Impact of Training on Industrial Performance

Training directly influences productivity, safety, and innovation. A well-trained workforce can operate with precision, respond quickly to issues, and continuously improve processes.

Operational Confidence

Trained personnel understand not just how to operate equipment, but why it behaves a certain way. This reduces hesitation during critical tasks and enables faster, more accurate decision-making. For example, knowing how to interpret a PLC fault code allows an operator to isolate the issue rather than calling external support for minor disruptions.

Reduced Downtime

When equipment malfunctions, trained staff can troubleshoot and resolve issues faster. They’re familiar with common failure modes, know how to navigate diagnostic tools, and can restart systems safely. This minimizes production losses and avoids unnecessary service delays.

Safety and Compliance

Training ensures that workers follow established protocols, reducing the risk of accidents, injuries, and regulatory violations. Whether it’s arc flash safety, machine guarding, or lockout/tagout procedures, knowledge is the first line of defense. In regulated industries like food, pharma, and chemical processing, training is also essential for documentation and audit readiness.

Cross-Functional Agility

Trained team members are more flexible and versatile. Operators who understand the basics of control systems can assist with maintenance. Technicians with process knowledge can support continuous improvement. This cross-functionality reduces bottlenecks and creates a more resilient workforce.

Retention and Workforce Development

Providing training opportunities contributes to job satisfaction and employee retention. People are more likely to stay in roles where they feel valued and supported in their growth. In sectors facing skills shortages—such as automation engineering—this is critical. Investing in training can help fill internal talent pipelines and reduce recruitment costs.

Standardization and Best Practices

Structured training ensures that everyone is working from the same playbook. This leads to consistent approaches across shifts, departments, and sites. It also helps standardize troubleshooting procedures, documentation, and escalation paths—reducing variability in system performance and maintenance outcomes.

Change Management

When introducing new equipment or processes, training is essential for adoption. It helps employees understand what’s changing, how it affects them, and what’s expected in the new workflow. This eases transitions, reduces resistance, and improves return on investment for new technology implementations.

Knowledge Retention and Succession Planning

Experienced employees eventually retire or move on. Without a plan to capture and pass on their expertise, companies risk losing valuable institutional knowledge. Training programs—especially those that include mentoring or digital content—help preserve this expertise and prepare the next generation of skilled workers.

Real-World Applications

- PLC Troubleshooting: Operators are trained to read diagnostic codes, interpret HMI messages, and reset faults safely

- Robotics Programming: Technicians learn to teach robot positions, test safety zones, and update motion sequences

- Electrical Maintenance: Staff are certified in isolation procedures, voltage testing, and safe panel entry

- Production Line Start ups: Teams receive pre-start training on sequence logic, alarm handling, and emergency stops

- Network Awareness: Engineers understand basic industrial Ethernet principles and can trace communication errors

These scenarios show how training contributes not only to productivity but also to the confidence and independence of technical teams.

The Role of Simulation in Training

Simulated environments allow trainees to explore scenarios that would be costly, dangerous, or disruptive to replicate on the factory floor. Simulation tools can replicate PLC programs, robotic paths, or production logic without the risk of damaging real equipment.

This is especially valuable for:

- Practicing fault recovery procedures

- Testing new automation logic

- Learning in a safe, consequence-free environment

- Onboarding new hires before site access

Simulation-based training bridges the gap between theory and practice, building competence before contact.

Training is not a one-time event, it’s an ongoing process that evolves with technology and operational needs. In industrial automation, where the margin for error is small and the pace of change is fast, training gives teams the tools they need to stay sharp, stay safe, and stay ahead. It’s an investment in people, and ultimately, in performance.