The Evolution of Automation

Robotics has fundamentally reshaped the landscape of industrial automation. From the early days of repetitive task automation to today’s intelligent, AI-driven robotic systems, the technology has evolved to meet the increasing demands of precision, flexibility, and efficiency. As industries face mounting pressure to innovate, robotics stands out as a cornerstone of future-ready manufacturing.

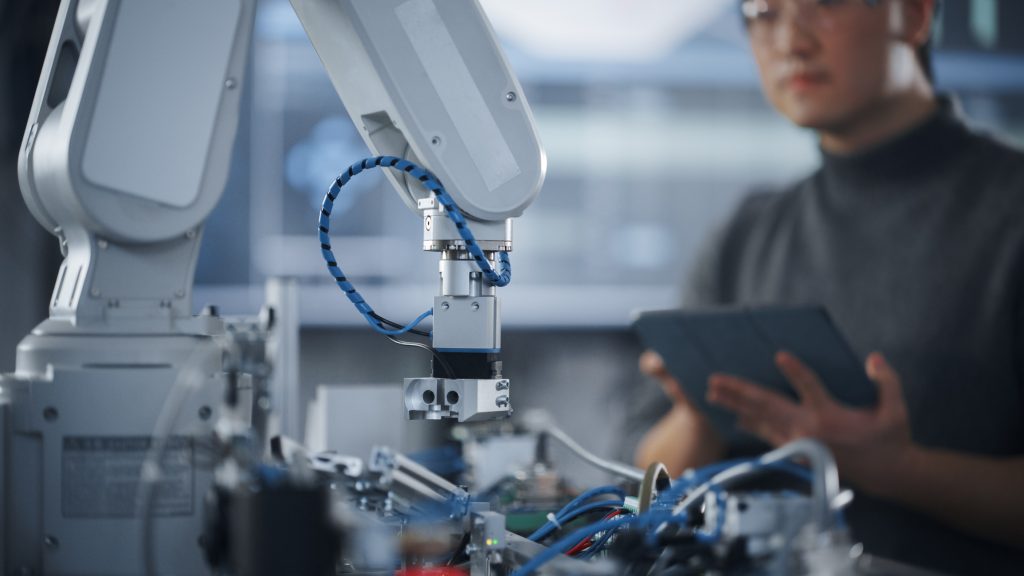

Understanding Industrial Robotics

Industrial robots are programmable, mechanical devices designed to perform tasks with speed and precision. Typically deployed in structured environments like factory floors, these machines range from simple pick-and-place robots to complex, multi-axis arms capable of advanced assembly, welding, and inspection.

Core components include:

- Actuators: Control movement (e.g., servo motors)

- End Effectors: Tools attached to the robot (e.g., grippers, welders)

- Sensors: Enable environmental awareness (e.g., vision, force feedback)

- Controllers: Direct the robot’s behaviour via software

The Impact of Robotics on Manufacturing

The integration of robotics into manufacturing has reshaped not just how products are made, but also how factories are designed, how supply chains operate, and how companies think about productivity. The true impact of robotics spans several dimensions—economic, operational, and cultural.

1. Productivity and Uptime

One of the most immediate and measurable benefits of robotics is the dramatic increase in output. Robots can run 24/7 without breaks, fatigue, or variation in performance. This allows production lines to scale up without the proportional increase in human labor, significantly boosting throughput. Additionally, robotics systems can be precisely timed and coordinated to reduce cycle times between operations, eliminating bottlenecks. In sectors where speed-to-market is critical—such as consumer electronics or pharmaceuticals—this becomes a key competitive advantage.

2. Workforce Augmentation

Rather than replacing human labor, robotics often enhances it. Robots handle monotonous or ergonomically difficult tasks such as repetitive lifting, high-precision assembly, or working in hazardous environments (e.g., with chemicals, extreme temperatures, or heavy machinery). Human workers are then freed to take on roles that require problem-solving, creativity, or nuanced decision-making. This shift not only improves job satisfaction but also elevates workforce capabilities through reskilling. In practice, an operator might move from a manual welding role to overseeing multiple robotic welders via a centralized interface.

3. Quality and Precision

Robots excel at performing tasks the exact same way every time. This level of repeatability drastically reduces variability and defects. For example, in the aerospace sector, where tolerances can be down to microns, even a slight deviation can lead to failure. Robotic arms equipped with force sensors and visual feedback systems can maintain this precision hour after hour, ensuring that every part meets strict quality standards. Fewer errors also translate to less waste, lower rework rates, and a more streamlined path from raw materials to finished product.

4. Safety Enhancements

Robotics contributes to safer workplaces by removing humans from high-risk tasks. In industries like mining, metal fabrication, or chemical processing, exposure to toxic substances, sharp tools, or high-heat environments is a constant concern. Robots can take on these duties with no risk to life or limb. Additionally, in environments where physical strain from heavy lifting or repetitive movement leads to chronic injuries, automation plays a preventive role. Safety benefits are not just about avoiding incidents—they also contribute to lower insurance premiums, better regulatory compliance, and a more positive workplace culture.

5. Data-Driven Operations

Modern robots are embedded with sensors that collect real-time data on performance, output, wear-and-tear, and environmental conditions. This data can be analyzed to optimize workflows, predict failures, and make better-informed decisions about everything from maintenance schedules to production planning. Over time, this contributes to a more agile and responsive factory floor—where decisions are driven by metrics rather than intuition.

6. Design Flexibility and Customization

Robotics enables manufacturers to shift away from rigid mass production toward more customizable workflows. By reprogramming robots or swapping end-effectors, production lines can be adapted quickly to build new product variants or small batch runs—ideal for markets that demand personalization or have short product lifecycles. For example, a robot used to assemble smartphones can be adapted to a new model with minimal downtime, dramatically reducing changeover costs.

7. Global Competitiveness

In many industries, the ability to automate efficiently determines a company’s position in the global market. Countries and manufacturers that adopt robotics early tend to build more resilient, cost-effective, and scalable operations. This, in turn, attracts investment, speeds up innovation, and opens up access to markets that would otherwise be out of reach.

Types of Industrial Robots

- Articulated Robots: Multi-jointed arms suitable for welding, packaging, and material handling.

- SCARA Robots: Fast and precise, ideal for pick-and-place applications.

- Delta Robots: Lightweight and high-speed, often used in food packaging.

- Cartesian Robots: Operate in straight lines, good for CNC and 3D printing.

- Collaborative Robots (Cobots): Designed to work safely beside humans without cages.

Collaborative Robotics: A Paradigm Shift

One of the most disruptive innovations in robotics has been the rise of collaborative robots, or cobots. Unlike traditional robots which require fenced-off areas for safety, cobots are built with safety mechanisms—force limiters, vision systems, and responsive sensors—that allow them to work alongside people.

They are:

- Easier to program (often via hand-guiding)

- Cost-effective for small and mid-sized businesses

- Ideal for tasks that require human oversight or interaction

This has lowered the barrier to entry for automation across industries.

Artificial Intelligence in Robotics

Modern robotics is increasingly infused with AI and machine learning. These technologies allow robots to:

- Recognize objects via computer vision

- Adapt to unstructured environments

- Optimize paths in real-time

- Perform predictive maintenance

AI-powered robots are no longer limited to static, repeatable tasks—they can adapt, learn, and improve over time.

The Future of Robotics in Industry

Robotics is at the heart of the next industrial revolution—what many call Industry 5.0. This new era focuses on synergy between humans and machines, where personalization, sustainability, and resilience are prioritized alongside efficiency.

Expect to see:

- Emotionally intelligent robots

- Greater interoperability through open standards

- Wider adoption in small-scale manufacturing

- Self-repairing and self-optimizing systems

Robotics is no longer just about automation it’s about transformation. As the technology becomes more accessible, intelligent, and collaborative, industries that embrace robotics are poised to redefine productivity, safety, and innovation. For engineers, operators, and decision-makers alike, understanding the evolving robotics landscape is crucial not just for staying competitive, but for shaping the future of work itself.