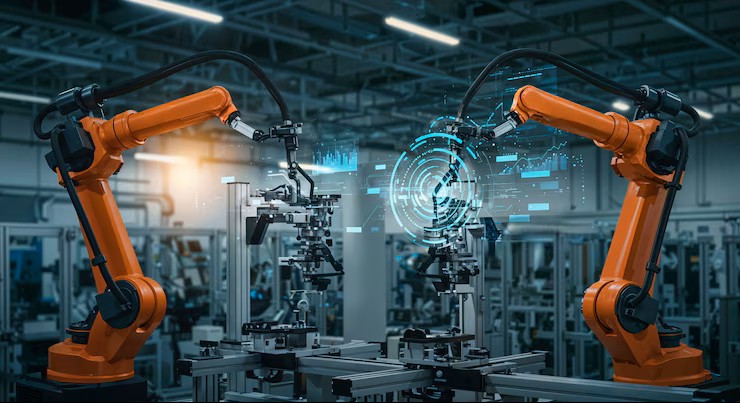

The Next Evolution of Machining

Traditional machining has long relied on CNC tools and fixed systems. While effective, these setups can be limited in flexibility and adaptability, especially when dealing with large, irregular parts or varying geometries. Robotic machining introduces a new layer of agility and reach, providing manufacturers with more versatile, efficient ways to shape, cut, and finish components across a wide range of materials.

What Is Robotic Machining?

Robotic machining refers to the use of industrial robotic arms to perform subtractive manufacturing tasks such as milling, drilling, grinding, routing, or cutting. Unlike CNC machines that move a tool across a defined axis within an enclosure, robotic systems offer six or more degrees of freedom—allowing greater movement, reach, and part accessibility.

A typical robotic machining setup includes:

- A multi-axis robot arm

- A high-speed spindle or cutting head

- Custom end-effectors or tool changers

- Sensors for force, torque, or vision feedback

- Integration with CAM or CNC software

This configuration allows robots to execute complex tool paths, even on large or asymmetrical parts.

The Impact of Robotic Machining in Industry

Robotic machining opens the door to more flexible and cost-effective production for low to mid-volume manufacturing, as well as large-format applications where traditional CNC is impractical.

High Flexibility and Reach

Robots can maneuver around large parts or complex shapes that would be difficult to orient within traditional machine beds. They’re ideal for machining 3D surfaces, molds, aerospace structures, boat hulls, and sculptures where multi-directional access is essential.

Cost Efficiency

Robotic machining cells often cost less than large-scale CNC machines, especially when considering footprint, power consumption, and infrastructure needs. With proper programming and calibration, they offer a highly attractive ROI for small-batch or custom operations.

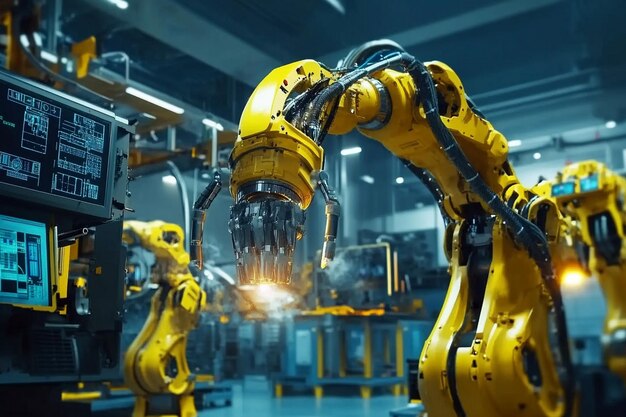

Adaptive Control and Smart Feedback

Robots equipped with force sensors and vision systems can adjust their path and pressure in real time. This enables consistent material removal across uneven surfaces or variable densities useful in woodworking, composites, or post-cast finishing where tolerances vary slightly.

Multi-Function Capability

Unlike fixed-purpose CNC systems, robotic arms can be equipped with interchangeable tools, allowing them to switch between milling, sanding, trimming, and inspection in one continuous workflow. This reduces changeover time and increases operational efficiency.

Lower Setup Time

For small-run or prototype jobs, robotic machining often requires less setup and fixturing than traditional methods. This makes it ideal for shops focused on custom fabrication or rapidly iterating designs.

Improved Workplace Safety

Automating cutting and grinding tasks reduces exposure to airborne particles, vibration, and noise making the shop floor safer for operators. Robots can work within enclosed, ventilated environments, handling hazardous materials or processes without human intervention.

Real-World Applications

- Aerospace: Milling large composite parts, trimming fiberglass, or drilling holes in fuselage sections

- Architecture & Art: Sculpting stone, foam, or wood into complex geometric forms

- Automotive: Light deburring of cast aluminium components and cutting plastic interior panels

- Boatbuilding: Machining large molds or hulls that exceed traditional CNC size constraints

- Foundries: Removing flashing or excess material from cast parts with high accuracy

These examples highlight how robotic machining adapts across industries, offering cost-effective solutions where traditional machines might fall short.

Programming and Simulation

Modern robotic machining relies heavily on advanced offline programming and simulation software. Engineers can simulate tool paths, test for collisions, optimize cut speeds, and generate G-code, all before touching the physical robot.

This digital workflow ensures:

- Better surface finish and dimensional control

- Minimal waste and rework

- Safer, faster deployment of new programs.

Popular platforms include Robotstudio, SprutCAM, RoboDK, etc

Robotic machining is a powerful addition to the modern manufacturing toolkit. By offering unmatched reach, flexibility, and adaptability, it enables manufacturers to automate complex machining tasks with lower overhead and greater design freedom. As software, sensors, and spindle technology improve, robotic machining will continue to expand its role across high-value, high-complexity production environments.