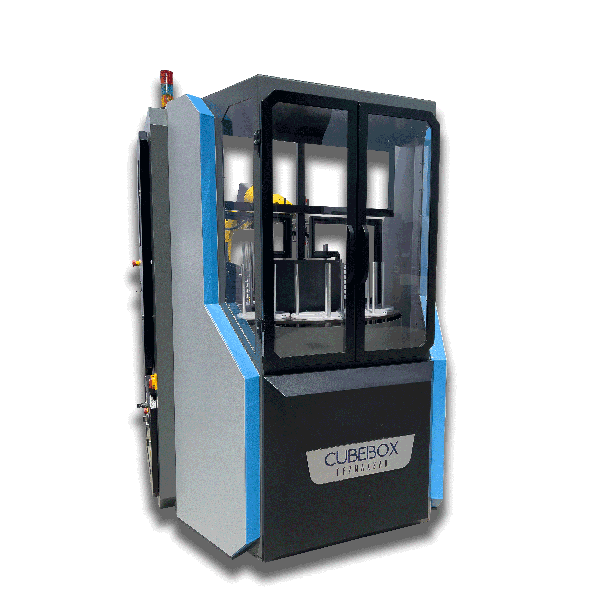

CubeBOX

Learn about CubeBOX Range

|

What is CubeBOX?

CubeBOX is a robotic automation system designed for Machine Tending in CNC environments. It integrates robot arms, conveyors, and vision systems to automate loading and unloading operations. The system enhances productivity, reduces labour costs, and ensures continuous operation with minimal human intervention. It features modular designs for compatibility with multiple sizes of CNC machines and brands. The system comes with RoboCAM software, this optimizes production and brings real-time tracking as well as remote monitoring capabilities.

- Information

- Specifications

- Documents

The CubeBOX Blues RT is a versatile robotic automation system designed to enhance CNC machine operations, particularly for lathes and vertical machining centers. Equipped with a 6-axis, 12 kg payload robot, it features a portable cell with a 1,100 mm rotary table and dual pallet stacker, accommodating workpieces up to 400 mm in height and diameters ranging from 5 to 120 mm. The system’s dual-pallet stacking capability allows for increased throughput without occupying additional factory space.

Installation is straightforward, facilitated by the user-friendly ROBOCAM software and a touch panel PC, enabling quick setup and operation without the need for experienced operators. The CubeBOX Blues RT is also portable, allowing easy relocation between machines, and is suitable for single, double, or multiple machine applications.

Incorporating the CubeBOX Blues RT into your manufacturing process can lead to increased productivity, reduced operator involvement, and enhanced operational flexibility.

- 6 Axis Robot 12 kg

- Portable Cell

1.100 mm - Rotationary Table – Dual Pallet Stacker

- Max. Workpiece height 400 mm.

- Steel Round Bar Workpiece Min. – Max. Diameter: 5 – 120 mm.

- Information

- Specifications

- Documents

The CubeBOX Blues RT-S is a robotic automation system designed to enhance CNC machine tending by automating the loading and unloading of workpieces. This system features a 6-axis industrial robot compatible with payloads of 12 kg, 25 kg, and 35 kg. It includes 11 metal trays, each measuring 800 mm by 500 mm, and is capable of tending up to two CNC machines simultaneously. The CubeBOX Blues RT-S offers easy and quick installation, is equipped with ROBOCAM software, and includes a touch panel PC for user-friendly operation. It’s suitable for single, double, or multiple CNC machine applications, providing flexibility in various manufacturing environments.

- 6 Axis industrial robot

- Compatible With 12 kg, 25 kg and 35 kg

- 11 pieces of Metal Tray (rack) 800mm. x 500 mm

- Suitable for tending up to 2 CNC machines.

- Information

- Specifications

- Documents

The CubeBOX Blues DR is a robotic automation system designed to enhance CNC machine tending by automating the loading and unloading of workpieces. This portable cell features a 6-axis robot with payload options of 12 kg, 25 kg, or 35 kg, and includes a stacker with 5 to 8 drawers, each measuring between 600 mm and 800 mm. It accommodates workpieces up to 135 mm in height and steel round bars with diameters ranging from 5 mm to 550 mm. The system offers easy and quick installation, is equipped with ROBOCAM software, and includes a touch panel PC for user-friendly operation. It’s suitable for single, double, or multiple CNC machine applications, providing flexibility in various manufacturing environments

- 6 Axis Robot 12 kg – 25 kg – 35 kg Payload

- Portable Cell

- 5 – 8 Drawer Stacker with 600 mm. – 800 mm. size each

- Max. Workpiece height 135 mm.

- Steel Round Bar Workpiece Min. – Max. Diameter: 5 – 550 mm.

- Information

- Specifications

- Documents

The CubeBOX Blues DR-3 Position is a robotic automation system designed to enhance CNC machine tending by automating the loading and unloading of workpieces. This system features a 6-axis industrial robot compatible with payloads of 12 kg, 25 kg, and 35 kg. It includes 5 to 7 drawers, each measuring 900 mm by 500 mm, and is capable of tending up to two CNC machines simultaneously. The CubeBOX Blues DR-3 Position offers easy and quick installation, is equipped with ROBOCAM software, and includes a touch panel PC for user-friendly operation. It’s suitable for single, double, or multiple CNC machine applications, providing flexibility in various manufacturing environments.

- 6 Axis industrial robot

- Compatible With 12 kg, 25 kg and 35 kg

- 5-7 Drawers with 900mm x 500mm size each

- Suitable for tending up to 2 CNC machines.

- Information

- Specifications

- Documents

The CubeBOX Blues DR Max-3 Position is an advanced robotic automation system designed to optimize CNC machine operations by automating the loading and unloading of workpieces. This system is compatible with 6-axis robots having payload capacities of 25 kg, 35 kg, or higher. It features 5 to 7 drawers, each measuring 1,300 mm by 500 mm, and is capable of tending up to three CNC machines simultaneously, enhancing operational efficiency. The CubeBOX Blues DR Max-3 Position accommodates steel workpieces with diameters ranging from 5 mm to 650 mm and hexagonal steel workpieces with side lengths between 10 mm and 450 mm. It offers easy and quick installation, is equipped with ROBOCAM Smart Automation software, and includes a touch panel PC for user-friendly operation. This system is suitable for single, double, or multiple CNC machine applications, providing flexibility in various manufacturing environments.

- Compatible With 25 kg / 35 kg and above 6 axis robot

- 5-7 Drawers with 1300mm x 500mm size each

- Suitable for tending up to 3 CNC machines

- RoboCAM Smart Automation software

- Min. Diameter of the Steel Workpiece** : 5mm

- Max. Diameter of the Steel Workpiece** : 650mm

- Min. Side Length of the Hexagonal Steel Work : 10mm

- Max. Side Length of the Hexagonal Steel Workpiece** : 450 mm

- Information

- Specifications

- Documents

The CubeBOX Blues DR MAX is an advanced robotic automation system designed to optimize CNC machine operations by automating the loading and unloading of workpieces. This system features a 6-axis industrial robot with a payload capacity of 35 kg or more, and includes a drawer stacker with 5 to 8 drawers, each measuring between 600 mm and 1,200 mm. It accommodates workpieces up to 135 mm in height and steel round bars with diameters ranging from 5 mm to 750 mm. The CubeBOX Blues DR MAX offers easy and quick installation, is equipped with ROBOCAM software, and includes a touch panel PC for user-friendly operation. It’s suitable for single, double, or multiple CNC machine applications, providing flexibility in various manufacturing environments.

- 6 Axis Robot 35 kg and above Payload

- 5 – 8 Drawer Stacker with 1.200 mm. – 600 mm. size each

- Max. Workpiece height 135 mm.

- Steel Round Bar Workpiece Min. – Max. Diameter: 5 – 750 mm.

- Information

- Specifications

- Documents

The CubeBOX Blues DR MINI is a compact robotic automation system designed to enhance CNC machine operations by automating the loading and unloading of workpieces. This system features a 6-axis robot with a payload capacity ranging from 7 kg to 12 kg. It includes a drawer stacker comprising 5 to 8 drawers, each measuring between 400 mm and 600 mm, accommodating workpieces up to 135 mm in height. The system is capable of handling steel round bar workpieces with diameters ranging from 5 mm to 350 mm. The CubeBOX Blues DR MINI offers easy and quick installation, is equipped with ROBOCAM software, and includes a touch panel PC for user-friendly operation. It’s suitable for single, double, or multiple CNC machine applications, providing flexibility in various manufacturing environments.

- 6 Axis Robot 7 kg – 12 kg Payload

- 5 – 8 Drawer Stacker with 400 mm. – 600 mm. size each

- Max. Workpiece height 135 mm.

- Steel Round Bar Workpiece Min. – Max. Diameter: 5 – 350 mm.

- Information

- Specifications

- Documents

The CubeBOX Vision is an advanced robotic automation system designed to optimize CNC machine operations through intelligent part handling. Equipped with a camera-based conveyor system, it enables smart part identification, eliminating the need for mechanical adjustments when switching between different parts. This flexibility is particularly beneficial in industries such as forging, where workpieces vary widely in dimensions and shapes.

The system features loading conveyors ranging from 800 mm to 2,250 mm and discharge conveyors from 800 mm to 3,000 mm, accommodating a diverse array of part sizes. Its compact and modular design allows for seamless integration into existing production lines without significant space requirements. Installation is straightforward, facilitated by ROBOCAM software and an intuitive touch panel PC, enabling quick setup and operation.

Implementing the CubeBOX Vision can lead to increased productivity and reduced operational costs by automating the loading and unloading processes of CNC machines. Its intelligent part recognition system ensures precise handling, minimizing errors and enhancing overall production efficiency. This makes it an excellent investment for manufacturers aiming to modernize their operations and maintain competitiveness in the evolving industrial landscape.

Installation is straightforward, facilitated by the user-friendly ROBOCAM software and a touch panel PC, enabling quick setup and operation without the need for experienced operators. The CubeBOX Blues RT is also portable, allowing easy relocation between machines, and is suitable for single, double, or multiple machine applications.

Incorporating the CubeBOX Blues RT into your manufacturing process can lead to increased productivity, reduced operator involvement, and enhanced operational flexibility.

- Loading Conveyor: 800mm – 2250mm

- Discharge Conveyor: 800mm – 3000mm

- Smart Part Identification With Camera

- No Need For Mechanical Adjustments On Different Parts.

- Flexible And Compact System Design

- Information

- Specifications

- Documents

The CubeBOX Soul series offers robotic automation systems designed to enhance CNC machine operations by automating the loading and unloading of workpieces. The series includes three models—Soul S, Soul M, and Soul L—each varying in size and capacity to accommodate different manufacturing needs.

The CubeBOX Soul S is the smallest in the series, with a robot payload capacity of 12 kg and cell dimensions of 2,150 mm in width and 1,700 mm in depth. It can handle steel round bars with diameters ranging from 5 mm to 200 mm and features 11 metal racks, each measuring 800 mm by 500 mm. The system is equipped with ROBOCAM software, a touch panel PC, and is designed for quick installation, making it suitable for single, double, or multiple machine applications.

The CubeBOX Soul M is a mid-sized solution with a robot payload of either 25 kg or 35 kg. Its cell dimensions are 2,500 mm in width and 2,000 mm in depth, making it slightly larger than the Soul S. This model accommodates steel round bars with diameters ranging from 5 mm to 180 mm and features 11 metal racks, each measuring 1,000 mm by 600 mm. Like the other models in the series, it offers user-friendly operation through ROBOCAM software and a touch panel PC and is designed for seamless integration into various manufacturing environments.

The CubeBOX Soul L is the largest model in the series, featuring a robot payload capacity of 35 kg or more. With a significantly larger cell size of 5,500 mm in width and 5,000 mm in depth, it is built to handle heavy-duty operations. It accommodates steel round bars with diameters ranging from 5 mm to 1,300 mm and includes 11 metal racks that are compatible with 1/2/3 Euro-pallet sizes. The system is designed for quick installation and easy operation through ROBOCAM software and a touch panel PC, making it highly flexible for single, double, or multiple CNC machine applications.

Each model in the CubeBOX Soul series is designed for easy integration and flexibility, catering to different manufacturing environments and operational needs.

CubeBOX Soul S

- 6 Axis Industrial Robot 12 kg. Payload

- Cell Width : 2.150 mm.

- Cell Length (Depth) : 1.700 mm.

- Steel Round Bar Workpiece Min. – Max. Diameter: 5 mm. – 200 mm.

- 11 pieces of Metal Racks 800 mm. x 500 mm.

CubeBOX Soul M

- 6 Axis Industrial Robot 25/35 kg. Payload

- Cell Width : 2.500 mm.

- Cell Length (Depth) : 2.000 mm.

- Steel Round Bar Workpiece Min. – Max. Diameter: 5 mm. – 180 mm.

- 11 pieces of Metal Racks 1.000 mm. x 600 mm

CubeBOX Soul L

- 6 Axis Industrial Robot 35 kg. and more Payload

- Cell Width : 5.500 mm.

- Cell Length (Depth) : 5.000 mm.

- Steel Round Bar Workpiece Min. – Max. Diameter: 5 mm. – 1.300 mm

- 11 pieces of Metal Racks of 1/2/3 Euro-pallet sized

- Information

- Specifications

- Documents

The CubeBOX Pallet Pool is a robotic automation system designed to enhance manufacturing efficiency by automating CNC machine tending. It features a compact cell with dimensions of 2,150 mm in width, 1,150 mm in depth, and a height of 1,815 mm, and a total weight of 1,200 kg (excluding the robot). The system offers easy and quick installation, is equipped with ROBOCAM software, and includes a touch panel PC for user-friendly operation. It’s suitable for single, double, or multiple machine applications, providing flexibility in various manufacturing environments.

- Cell Width : 2.150 mm.

- Cell Length (Depth) : 1.150 mm.

- Cell Higth / Fence Hight : 1.815 mm.

- Standard Cell Total Weigth (without robot) : 1.200 Kg.

- Information

- Specifications

- Documents

The CubeBOX Space Cabinet is a robotic automation system designed to optimize CNC machine operations by automating the loading and unloading of workpieces. This portable system features a compact cell with dimensions of 2,150 mm in width and 1,700 mm in depth, making it suitable for various manufacturing environments. It accommodates steel workpieces with a maximum diameter of 100 mm. The system includes three drawers for holding products, which are unloaded using a 6-axis robot, reducing the need for frequent restocking. When replenishment is necessary, the ergonomic design allows the drawers to be rolled into a convenient position for easy parts supply. The CubeBOX Space Cabinet offers easy and quick installation, is equipped with ROBOCAM software, and includes a touch panel PC for user-friendly operation. It’s suitable for single, double, or multiple CNC machine applications, providing flexibility in various manufacturing environments.

- Cell Width : 2.150 mm.

- Cell Length (Depth) : 1.700 mm.

- Max. Diameter of the Steel Workpiece : 100 mm.

- Portable System

- Flexibility To Load And Unload Parts While Working

- Information

- Specifications

- Documents

The CubeBOX ServoDOOR is a universal automation system designed to enhance CNC machine operations by automating the opening and closing of machine doors. Compatible with both new and existing CNC machines across various brands, it aims to improve work safety by protecting operators from injuries and accidents. By communicating directly with the CNC system, the ServoDOOR minimizes operator errors and malfunctions. It is energy-efficient, consuming power equivalent to a 65W light bulb during operation, thereby keeping energy costs minimal. The system is available in multiple configurations, including single door, double door single unit, and double door double unit models, all equipped with servo motors to suit different CNC machine setups.

- CubeBOX ServoDOOR – Single Door

CubeBOX ServoDOOR You can use the single door model for your CNCs. Our one-door models are equipped with servo motors.

- CubeBOX ServoDOOR – Double Door

You can use the CubeBOX ServoDOOR double door single unit model for your double door CNCs. We have models equipped with servo motors.

- CubeBOX ServoDOOR – Double Door Double Unit

You can use the CubeBOX ServoDOOR double door double unit model for your double door CNC machines. We have models equipped with servo motors.