Merging Robotics with Additive Manufacturing

3D printing has already transformed prototyping and small-batch production but traditional systems are often limited by their fixed build volumes and motion constraints. Enter robotic 3D printing: a powerful fusion of additive manufacturing and industrial robotics. By combining multi-axis robotic arms with extrusion heads, this approach unlocks a new level of flexibility, scale, and geometry in the world of additive production.

What Is Robotic 3D Printing?

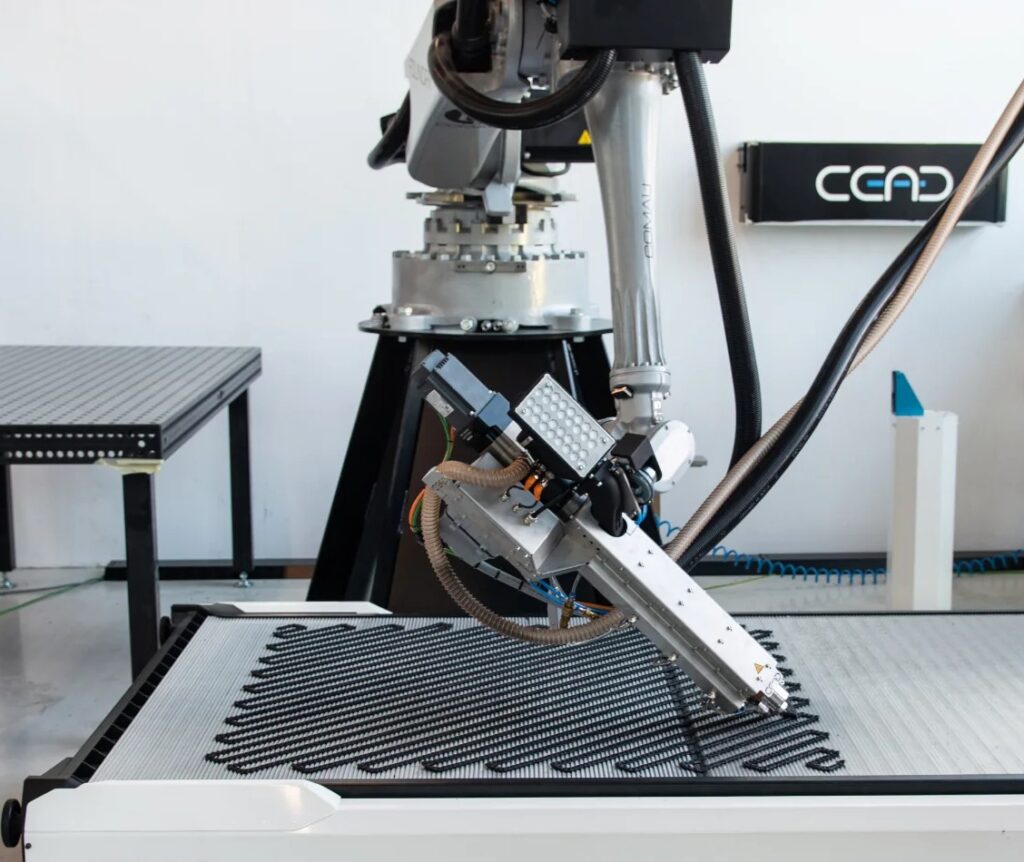

Robotic 3D printing involves mounting an extrusion tool usually for thermoplastics, composites, or concrete onto a robotic arm. Unlike traditional 3D printers that operate on three linear axes (X, Y, Z), robotic systems offer six or more degrees of freedom. This allows curved layer paths, printing on non-horizontal surfaces, and the creation of large, continuous geometries.

A typical robotic 3D printing setup includes:

- A multi-axis industrial robot

- An extrusion or deposition head (filament, pellet, paste, or slurry)

- Heated beds or print platforms (optional)

- Slicing software tailored for robotic motion paths

- Safety enclosures and material handling systems

This setup enables printing of components several meters in length, with shapes not achievable using Cartesian-based printers.

The Impact of Robotic 3D Printing in Industry

Robotic 3D printing is helping manufacturers break through traditional additive constraints bringing additive capabilities to architecture, automotive, aerospace, construction, and more.

Large-Scale Fabrication

Traditional 3D printers are often confined by their gantry size. Robotic arms can extend the printable area in all directions, allowing creation of furniture, vehicle components, architectural structures, and tooling without the need for assembly or segmentation.

Complex Geometry and Multi-Axis Control

With robotic movement, objects can be printed in spirals, arcs, overhangs, or even on curved surfaces. This opens up design freedom for non-planar structures, continuous reinforcement paths, and integrated joint features. It also eliminates the need for support structures in many cases.

Toolpath Customization

Robotic slicing software allows engineers to define toolpaths that follow the natural geometry of a part. This can improve strength by aligning layer lines with force directions or reduce material usage by optimizing deposition.

Toolpaths can also be programmed manually or generated from parametric designs in Rhino, Grasshopper, Fusion 360, Robotstudio or similar platforms.

Versatile Material Options

Robotic 3D printers can be adapted to work with:

- Thermoplastics and composites (ABS, PLA, PETG, carbon-fiber reinforced materials)

- Concrete and cementitious materials for construction

- Clays and ceramics for architectural or artistic uses

- Metal paste or cold-welding materials for prototyping

Each material type requires different nozzles, temperatures, and flow rates—but the robotic platform can adapt to all with the right extruder and control logic.

Real-World Applications

- Construction: Printing walls, facades, or molds on site using concrete or geopolymer paste

- Furniture Design: Creating custom chairs, tables, and decorative structures in plastic or recycled material

- Aerospace: Producing large aerodynamic forms, jigs, and fixtures with low weight and complex geometry

- Automotive: Printing custom dashboards, spoilers, or tooling components

- Art and Sculpture: Enabling creative expression through curved, multi-dimensional printed forms

These applications show how robotic 3D printing supports both functional and creative outputs across industries.

Integration with CAD and CAM

Robotic 3D printing relies on tight integration between design software and motion control. Common workflows involve slicing models into print paths using robotic-aware CAM tools, then simulating the process for collision checking and kinematics.

Offline programming platforms like Robotstudio, RoboDK, SprutCAM, and Grasshopper plugins provide visual, customizable toolpath creation.

Benefits Over Traditional 3D Printing

- Scalability: Print objects larger than the machine’s footprint

- Freedom of Movement: Create parts with curved layers and fewer supports

- Customization: Adapt the process for different applications with swappable tools

- Reduced Assembly: Produce single large parts rather than gluing or welding segments

- Cross-Disciplinary Flexibility: Apply the same platform to art, construction, design, and engineering

These advantages make robotic 3D printing an attractive choice for organizations working with complex or non-standard geometries.

Robotic 3D printing blends the versatility of additive manufacturing with the flexibility of industrial robotics creating a powerful tool for designers, engineers, and fabricators. It breaks free from the limitations of gantry-based systems, enabling large-scale, multi-axis, and non-planar printing for applications that demand scale, freedom, and form. As software and materials evolve, robotic 3D printing is set to redefine how we design and build in three dimensions.